Material Demander for Member Activities of a Knowledge Service Brand

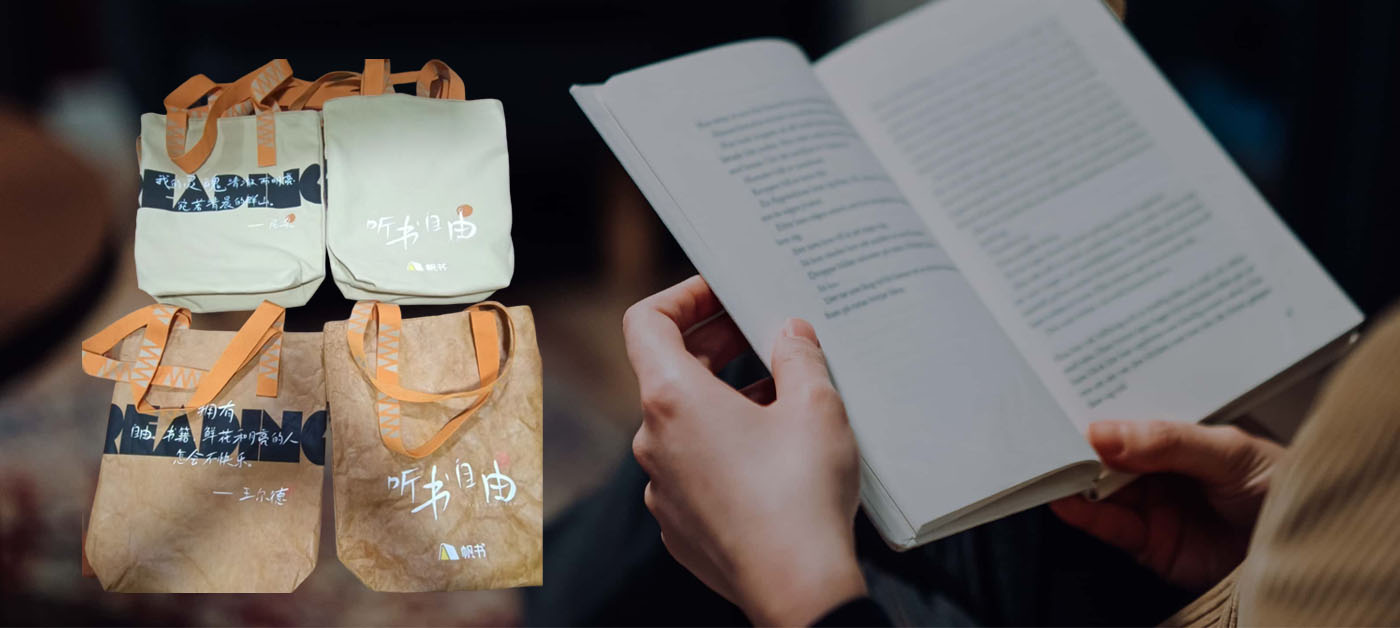

Fandeng Reading (official website: www.fandeng.com) is a well-known domestic knowledge service platform. In 2023, it customized 15,000 Dupont paper bags as gifts for its member recharge activity to reward users. As a brand focusing on "quality content + user experience", it has high requirements for the design sense (double-sided reversible creativity) and delivery efficiency (matching activity schedule) of activity materials, requiring reliable suppliers to support activity implementation.

Customize 15,000 double-sided reversible Dupont paper bags that fit the brand tone for gifts in member recharge activities. Since at least 7,500 bags need to be delivered by the 15th for the activity, it is necessary to complete the entire process of "plan confirmation, sampling, and production" in a short cycle to ensure timely availability of activity materials.

Challenges Faced

Delayed plan and sampling: Only a design draft was provided, with the plan unconfirmed and sampling not started. In addition, the double-sided reversible structure needed to verify feasibility, directly affecting the production start time.

Urgent delivery pressure: 7,500 bags needed to be delivered by the 15th, with an extremely short overall cycle. The conventional process of "confirm plan → sample → prepare materials → produce" could not meet the demand.

Structural process risks: The double-sided reversible design requires high precision in cut piece alignment and folding. Sampling needed to test structural stability simultaneously.

First-batch delivery constraints: Priority had to be given to ensuring the first batch of 7,500 bags, then completing the remaining 7,500, requiring precise splitting of production schedules.

Solutions

Parallel processes to shorten the cycle: Communicated plan details with the client synchronously and predicted sampling directions based on the design draft; simultaneously started "sampling testing" and "raw material preparation" (locked Dupont paper supplier capacity). Production was immediately launched after plan confirmation, saving 3 days of material preparation time.

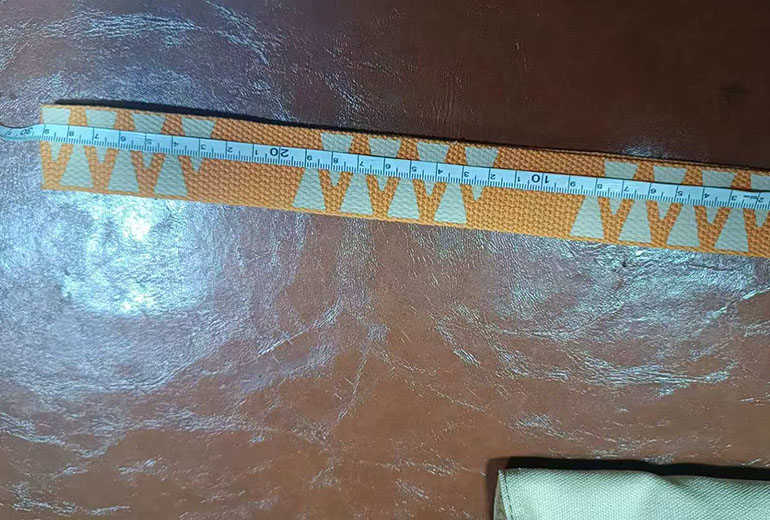

Process optimization for double-sided structure: For the double-sided reversible requirement, sampling focused on testing "folding alignment precision" and "load-bearing durability", adjusted cut piece sizes and folding creasing processes to ensure structural stability; the first batch of 7,500 bags was prioritized for production, using the "dual-line production + batch quality inspection" mode to ensure delivery.

Collaborative communication mechanism: Established a special docking group to feedback sampling progress within 2 hours and update material preparation status within 4 hours, allowing the client to grasp the process in real-time; informed the delivery nodes of the first and second batches in advance and provided logistics tracking plans simultaneously.

15,000 Dupont paper bags were delivered 2 days in advance, with the first batch of 7,500 meeting the activity needs on time. The double-sided reversible structure was stable and of qualified quality, winning user recognition. This cooperation prompted Fandeng Reading branches to recommend Gahumi to the headquarters and Beijing branch, making Gahumi its core supplier and laying a foundation for subsequent cooperation in activity materials.

🚩About the Client

FanBook focuses on knowledge dissemination and member services. Member activities are core scenarios to enhance user stickiness, with strict standards for "creative adaptation" and "reliable delivery" of activity materials. It values suppliers' "risk response capabilities" and "collaborative efficiency", and high-quality partners will get cross-regional recommendation opportunities.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric product enterprise integrating R&D, design, production, and sales, with 31 years of customization experience. Relying on a flexible production system and rapid response capabilities, it excels in meeting "short-cycle, high-risk" customization needs. Through process optimization and collaborative communication, it provides efficient material solutions for brand activities and is trusted by clients in knowledge services, retail, and other fields.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Customer Testimonial

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap